Spares and Criticality: A Missed Link in Asset Management

When a critical asset fails, it's not just the equipment that stops - it's your operations, your deadlines and potentially, your customer trust. But what if the root cause wasn’t the asset, but the missing spare part?

In asset-intensive industries, spare parts are often the unsung heroes of operational resilience. Yet too often, they are treated as an afterthought. This oversight can undermine even the best-laid maintenance strategies.

What Is Criticality and Why Does It Matter?

Asset criticality refers to the relative importance of an asset based on the consequences of its failure. A criticality assessment typically considers safety, environmental impact, production loss, financial cost and regulatory implications. It forms the backbone of a risk-informed maintenance approach, guiding everything from inspection frequency to resource prioritisation.

Yet one area where criticality often fails to be fully integrated is in spares management. While maintenance regimes are increasingly driven by criticality scores, spare parts are frequently stocked (or not stocked) based on intuition, tradition, or past consumption rather than actual risk.

The Disconnect: Spares in Isolation

All too often, inventory strategies are reactive. Procurement teams stock parts based on usage history without accounting for risk or lead time. Conversely, they may fail to stock a vital component simply because it hasn't failed recently. The result? Overstocked shelves of low-value consumables and urgent, costly procurement of critical items when failure strikes.

The challenge is compounded by a lack of cross-functional alignment. Engineering defines what’s critical; procurement focuses on cost and turnover; stores manage space and stock levels. Without a unifying strategy based on criticality, the spares supply chain becomes fragmented and inefficient.

Why Spares Strategy Should Mirror Asset Criticality

Spare parts should be treated as strategic enablers of reliability - not just consumables. The criticality of an asset should directly influence how its spare parts are managed. This includes:

Stocking Policy

Critical assets with long-lead or specialist components require assured availability. These parts must be held in stock or have guaranteed supplier agreements.

Inventory Control

Non-critical assets can rely more on supplier responsiveness, avoiding unnecessary capital lock-up.

Supplier Strategy

For high-criticality assets, build relationships with OEMs or approved vendors to ensure availability.

Lifecycle Tracking

Spare parts associated with high-risk assets should be monitored for obsolescence and condition.

In essence, your spares strategy should be an extension of your criticality matrix.

A Real-World Example

Aligning Spares to Criticality: Where to Begin

Here are practical steps for aligning your spares strategy with asset criticality:

Revisit Your Asset Criticality Assessment: Ensure your asset ranking is up to date and reflects current operations.

Map Spares to Assets: Link each part to the equipment it serves and its associated criticality score.

Assess Lead Time and Failure Risk: Identify which parts are long-lead or obsolete and what the consequences of failure would be.

Adjust Stocking Policies: Prioritise stocking based on both usage and risk.

Leverage CMMS and Analytics: Use data to monitor stock levels, track usage and inform future decisions.

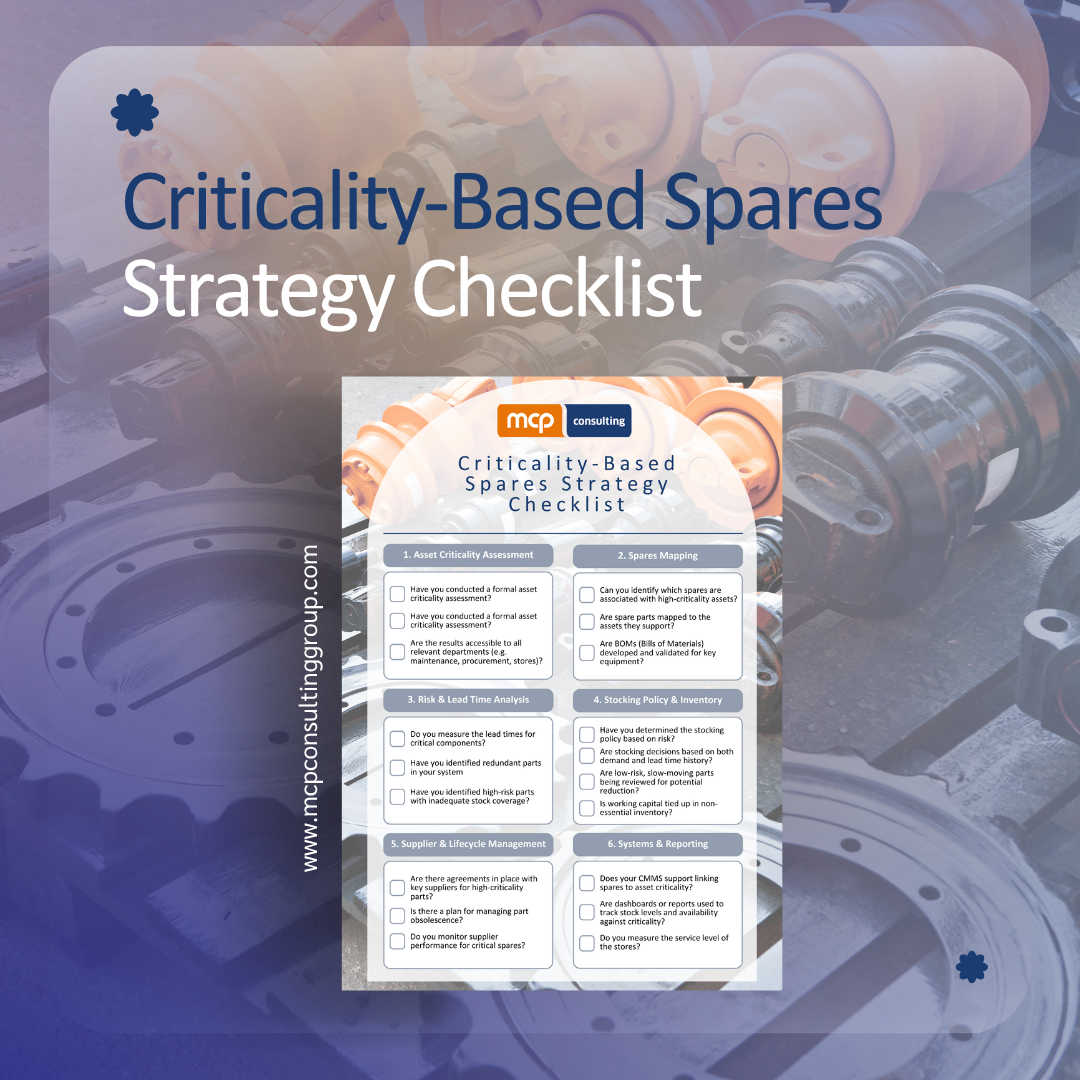

Use this quick-reference tool to evaluate your current approach and identify key improvement areas across inventory, procurement and maintenance.

From Spare Parts to Strategic Assets

Spares may not fail - but their absence can. Without them, even the best-maintained assets are vulnerable. By integrating spares management with asset criticality, organisations can bridge a longstanding gap in asset management and unlock new levels of efficiency, resilience and cost control.

Want to assess your spares strategy? Talk to MCP about how we can help align your inventory practices with asset risk and operational performance.