Maintenance Improvement Roadmap

A clear journey to stronger maintenance performance

Every organisation sits at a different point in its maintenance journey. Some are focused on stabilising day‑to‑day performance. Others are refining reliability, cost control, and long‑term asset strategies. The MCP Maintenance Improvement Roadmap brings these realities together into one clear, structured view.

Developed by MCP’s CEO, Peter Gagg and consulting team, this roadmap shows how maintenance improvement works in practice – step by step, over time – and how MCP supports organisations at every stage, whether you are just starting or struggling with the next steps.

One roadmap.

Many steps.

The MCP Maintenance Improvement Roadmap is designed around a simple truth: historically no two organisations are in the same position and progress is not linear. What matters is clarity on where you are now, what you have missed, what comes next and how today’s actions connect to long‑term results.

The MCP Maintenance Improvement Roadmap:

1

Makes improvement programmes easier to understand

This is the framework has been developed with clients across manufacturing, process industries and complex facilities.

2

Shows how individual activities connect into a coherent system

3

Following the roadmap will help deliver consistency and added value

Download

Roadmaps | Maintenance Improvement

Get access to our interactive Maintenance Improvement Roadmap and find out where you are.

The access includes:

Maintenance Improvement Roadmap

Operator Asset Care Roadmap (OAC)

Reliability Programme Roadmap

Spare Parts Management Roadmap

Maintenance Technical Strategy Roadmap

What we can support

Common maintenance challenges we see

Most organisations don’t struggle because they lack effort. They struggle because improvement activities are fragmented, reactive, or disconnected from longer-term goals.

Typical challenges include:

Reactive maintenance dominating the workload

1

Poor asset data and limited visibility

2

Reactive maintenance dominating the workload

3

Poor asset condition and replacement decisions

4

Skills gaps and unclear responsibilities between operations and maintenance teams

5

6

Rising costs without a clear line of sight to value

These challenges look different in every organisation, but they tend to stem from the same root cause:

improvement activities are not connected into a single, coherent journey.

What’s inluded

How the roadmaps fit together

The main roadmap is made up of interconnected specialist roadmaps. Each can be addressed independently, but delivers greatest value when aligned as part of a single improvement programme.

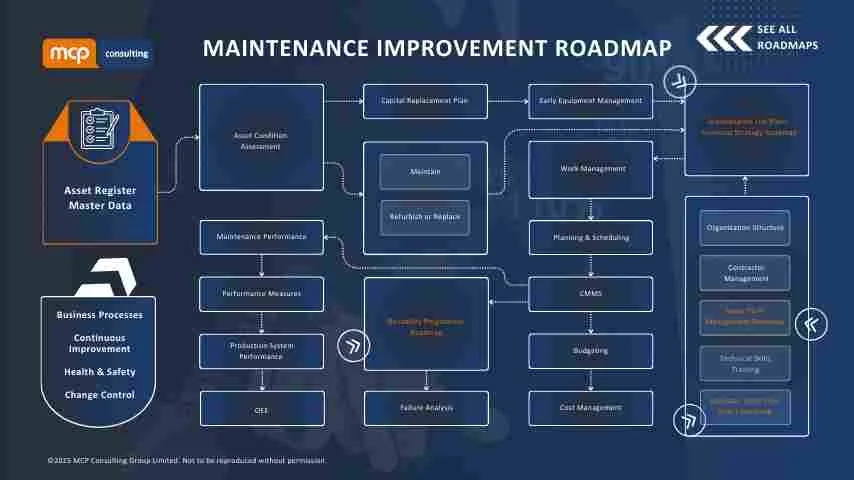

Maintenance Improvement Roadmap

Provides the overall structure, linking governance, processes, asset decisions, and performance management.

Operator Asset Care (OAC) Roadmap

Defines how operators and maintenance teams work together to protect assets and improve day-to-day performance.

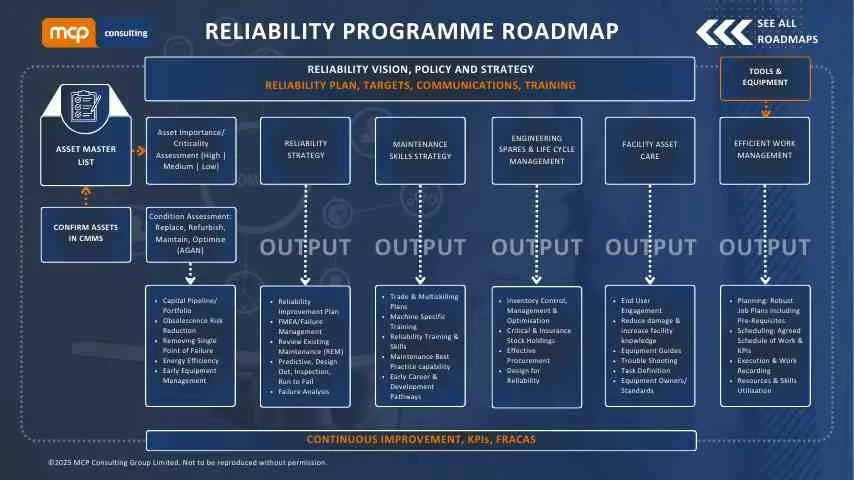

Reliability Programme Roadmap

Focuses on asset criticality, failure analysis, maintenance strategies, and long-term reliability planning.

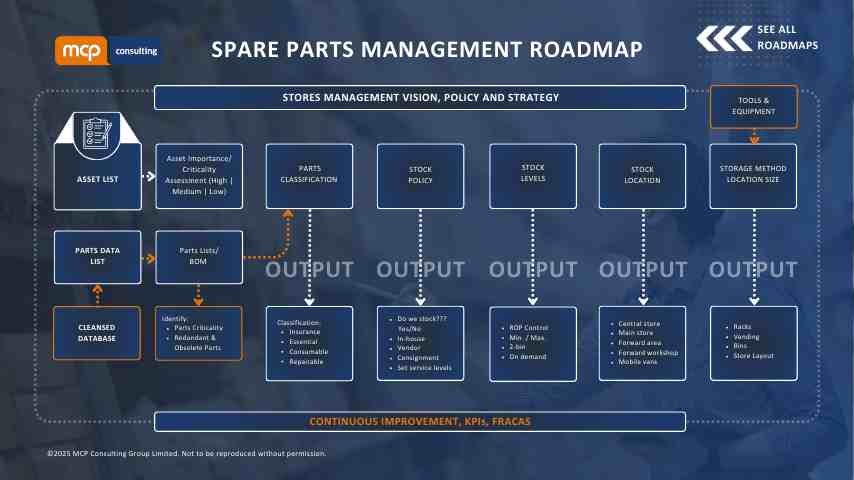

Spare Parts Management Roadmap

Addresses inventory control, critical spares, obsolescence, stock policies, and lifecycle management.

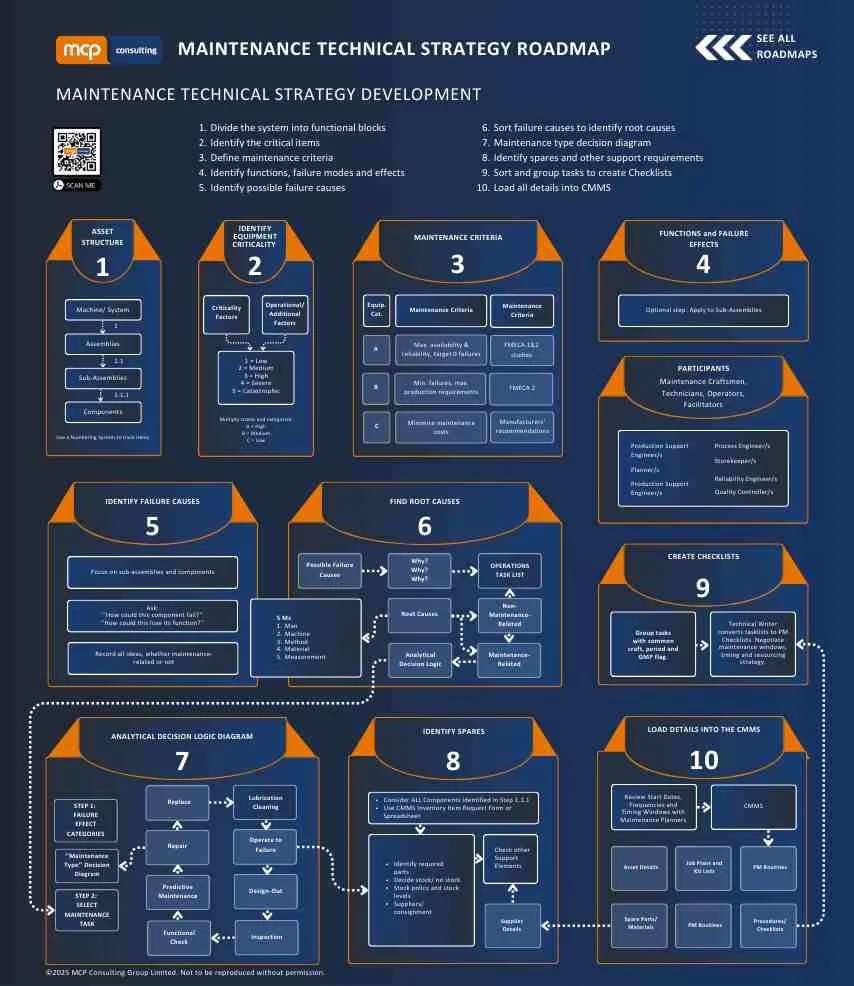

Maintenance Technical Strategy Roadmap

Provides a structured approach to defining maintenance tasks, frequencies, aligned to objectives.

Cost savings roadmap – available on request

Alongside maintenance improvement, MCP has developed a dedicated Cost Savings Roadmap focused on measurable financial outcomes, including:

Maintenance cost reduction

Capital expenditure reduction

Inventory and procurement efficiencies

OEE and energy performance improvements

This roadmap is a valuable source of information built on years of hands-on experience and can be accessed on request.

FAQs

-

A maintenance improvement roadmap is a structured framework that shows how maintenance activities, processes, people, and asset decisions connect over time. It helps organisations move away from fragmented initiatives and towards joined-up, sustainable improvement.

-

MCP’s roadmap is built from real consulting delivery, not theory. It connects governance, work management, reliability, skills, and data into one coherent journey and allows organisations to engage at any point without forcing a rigid maturity model.

-

No. Organisations who use the roadmap may be at different stages. Some are stabilising core maintenance processes, while others are refining reliability or asset replacement strategies. The approach can take into account your current challenges.

-

Yes. Each specialist roadmap — including Maintenance Improvement , Operator Asset Care (OAC), Reliability Programme, Spare Parts Management and Maintenance Technical Strategy can be applied on its own. The overall roadmap ensures these efforts remain connected rather than isolated.

-

The cost savings roadmap translates maintenance improvement into measurable financial outcomes, such as reduced maintenance spend, optimised inventory, improved OEE, and lower capital expenditure.