How to Out-Smart Your Facility

A smarter approach to maintenance, no matter the age of your building or equipment.

The Intangible Task

If you're responsible for a building, manufacturing plant, or industrial facility, you're likely aware of how the Industrial Internet of Things (IIoT) is transforming maintenance strategies. Yet many facilities, even those built within the last 10 years, are already burdened by outdated systems. What once felt cutting-edge is now considered legacy.

It can seem unrealistic to retrofit smart technology into an older setup but that’s where innovation steps in.

Here’s how you can out-smart your facility, no matter its age or complexity.

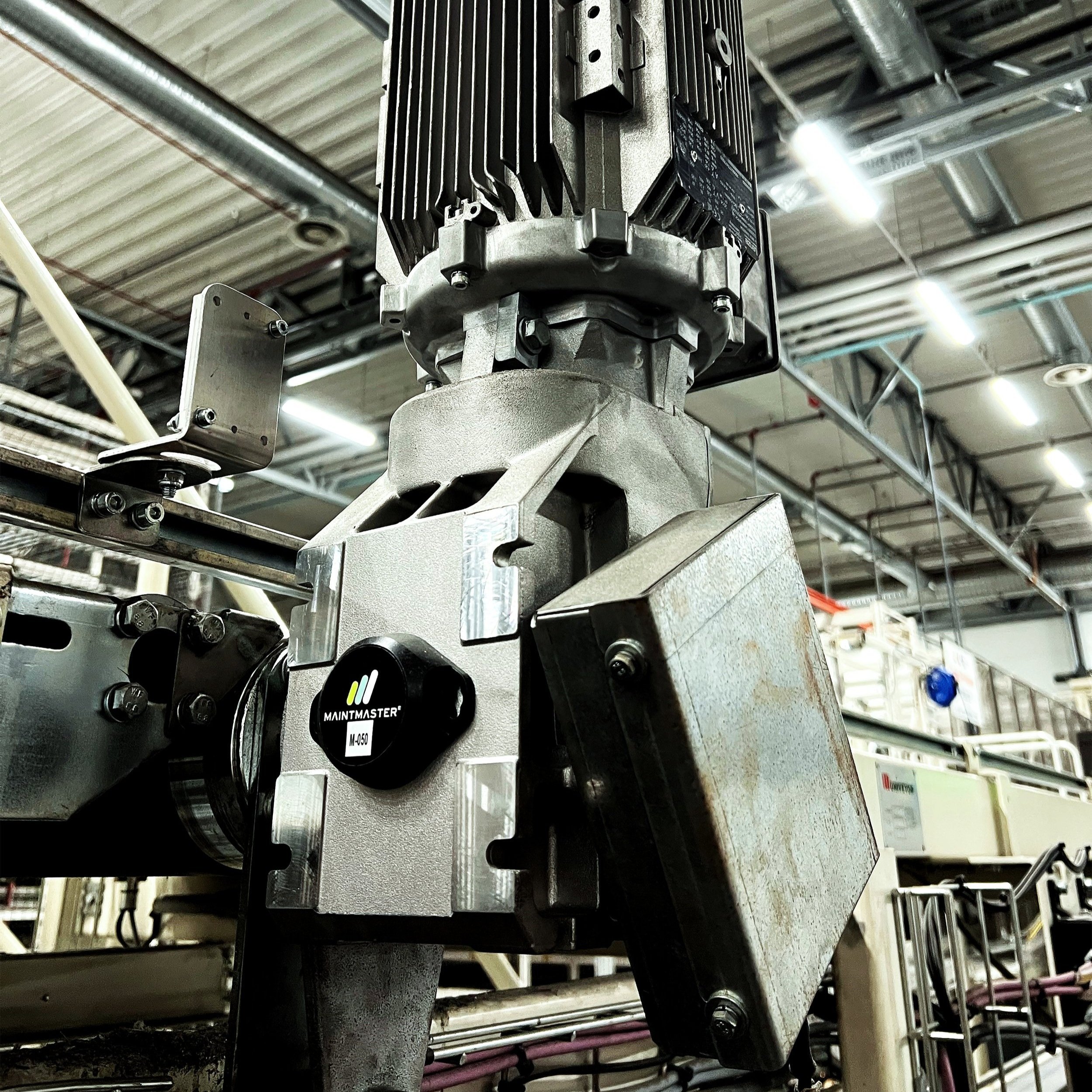

Retrofit Smart Technology That Works

The idea of retrofitting isn’t new but the reality of it has changed. Here are some of the most common concerns we hear from our customers and how modern IIoT technology overcomes them:

“Our systems are too old.”

Even relatively modern systems are now considered outdated. But the latest retrofit solutions feature universal-fit sensors that can be installed on almost any type of equipment, regardless of age, manufacturer, or location — without disrupting existing infrastructure.

“We don’t have the infrastructure to power new sensors.”

Traditional sensors needed a dedicated power source, which made retrofitting costly and impractical. Today’s IIoT sensors use energy harvesting technology, they generate their own power from surrounding conditions. They’re wireless, self-powered and maintenance-free (no battery changes required), with software updates delivered through the cloud.

“Conditions are too harsh for sensors.”

Some sensors are designed to function in extreme industrial conditions, including high temperatures (up to 140°C), damp environments and electromagnetic interference. They’re immune to ambient light and environmental noise, making them ideal for production, utilities and heavy-duty environments.

“We can’t attach sensors to the equipment.”

If mounting a sensor isn’t feasible, contactless options are available. These can monitor machinery without direct contact, even in high-heat, wet or hard-to-reach areas. This also means no manufacturer approvals or additional certifications are required, particularly for sensitive or hazardous zones.

“Our software isn’t compatible.”

No problem. Some sensors use robust radio communication protocols to send data to a central Gateway, with a range of 80–120m in harsh conditions and up to 500m in open areas. That Gateway feeds data into a secure cloud platform or integrates easily into your existing CMMS or monitoring system.

“We don’t have in-house IIoT expertise.”

You don’t need it. Once installed, sensors are easily managed through a secure cloud platform (IEC/ISO 27001-compliant). You can view dashboards, receive alerts, and set rules for automated actions, all with minimal training.

“We run to failure — it works for us.”

For some non-critical assets, a Run to Failure approach is acceptable. But critical systems benefit from predictive or prescriptive maintenance strategies that save cost, reduce downtime, and extend asset life. IIoT makes this shift achievable without overcomplicating your operation.

“We don’t have the budget.”

IIoT has become significantly more cost-effective. With no wiring, no batteries, and no need for additional infrastructure, the cost to implement is lower than ever and the ROI is now measurable through reduced downtime, optimised maintenance schedules, and improved asset performance.

The real question is: Can you afford not to?

Let’s Start to Out-Smart

Objections to IIoT are becoming less convincing by the day. Facilities that embrace smart maintenance are already seeing improvements in uptime, efficiency and cost control - while those sticking to traditional methods risk falling behind.

If you’re ready to take a smarter approach to maintenance, we’re ready to help.

Let’s out-smart your facility — get in touch to arrange a consultation.

Complimentary eBook - Guide to the IIoT

The purpose of our eBook - Guide to the IIoT, is to describe some of the concepts of the Industrial Internet of Things and how you can get started on your journey. We provide suggestions on what companies can do to get equipment connected, start gathering data and put the data to use.

In our eBook - Guide to the IIoT, we cover:

An overview of Industry 4.0

How the IIoT works

The downsides of IIoT

Overview of maintenance strategies

How to start your IIoT journey

The benefits of the IIoT

Frequently asked questions